NQ1965

PR Elite

I originally intended to post this in the Winter Projects re-re-re-re-revisited thread but while browsing the site on Friday it hit me that we just don't get the number of new threads in the Old Bike section that we used to. So I felt that this one was worthy of a fresh post.

A brief history of me and this bike: Way back when I was 34 this was the very first dirt bike I had bought since I was a teenager. Our kids were all older, and we had hit some financial goals and finally decided it was time. I've never considered selling the bike, and it's still one of my most favorite in the stable.

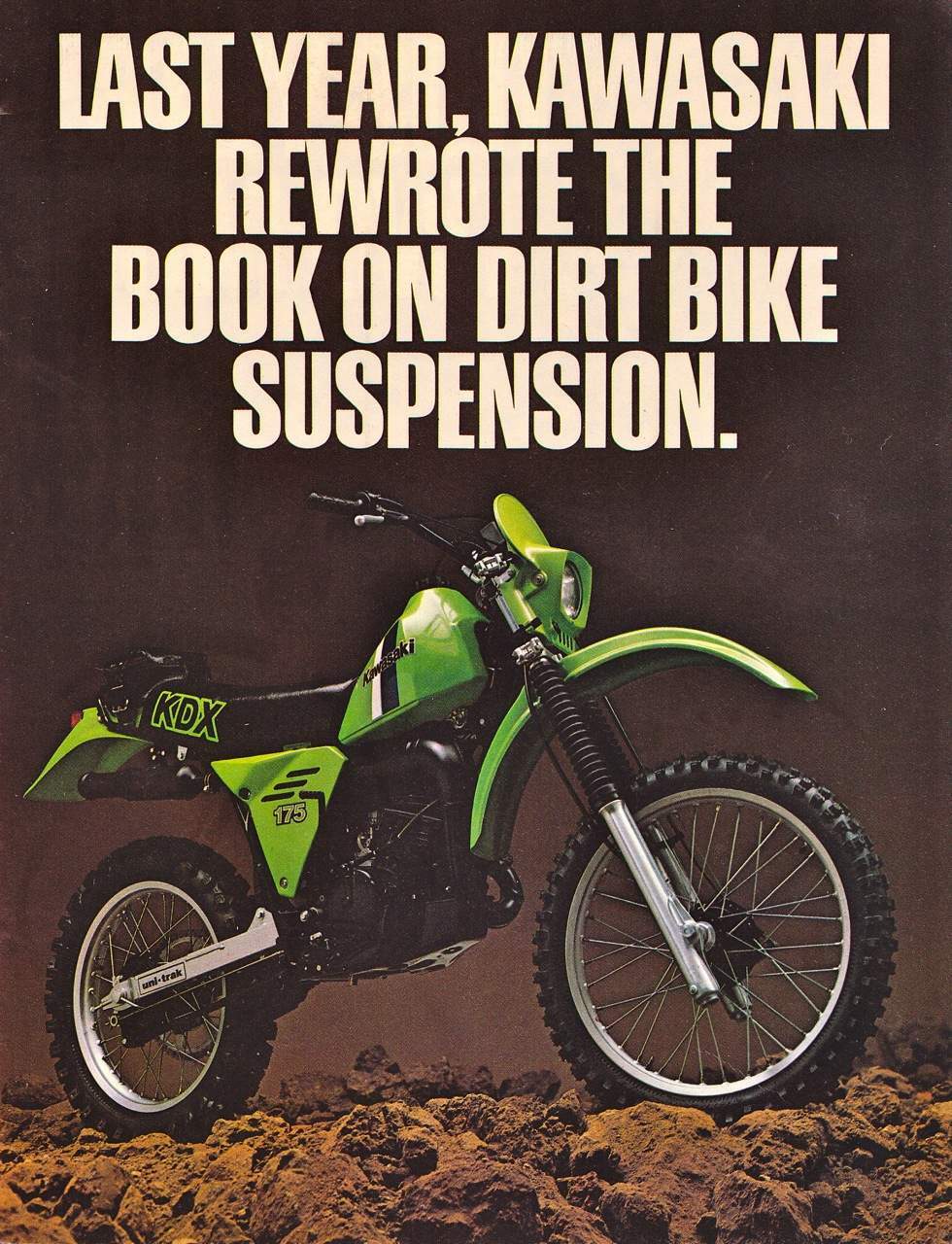

Most of you guys have read numerous postings of me talking about my KDX175 from the Vintage Days posts over the years, so nothing new there. This year it got raced again but rendered me my 1st DNF in the CC race. I knew last year it needed a tear down but couldn't get to it, but now it's time.

It also occurred to me that as far as Vintage/PV/Evolution bikes go, there are very few of us Kawasaki racers on here.

Another thought that I had leading into this is that even though we have a lot of Pitracer members that do rebuild their bikes, they tend to leave out the gritty details and struggles that I love to see and read about. So I've decided to go a little bit in-depth as I tear down and get this bike back together again for the 2018 season.

So here we go.

Last edited: